To ensure the best quality of the products we offer, the printing house is equipped with the most modern production lines, and at the same time, modern printing technologies based on German machines have been implemented, which guarantee the highest quality of printing and binding.

On an area of 3,800 m2, the newly built halls included:

Quality control

Prepress

After sending us production files made according to the guidelines included in the attached PDF document, the files will be assembled by our editors and exposed to plates.

Proper preparation of the production file is one of the conditions for obtaining a high-quality print. Before making printing plates, it is possible to make a digital proof, which can be used as a color or ozalid pattern to check the correctness of assembly.

In our printing house, during the production cycle, files are exposed using CtP technology on modern imagesetter, which, together with the machinery, guarantees the highest quality of printing.

The newly introduced CtP system has the potential to significantly increase efficiency in the printing house, thanks to which we are able to offer the highest quality materials. Whether you need compact design, performance, reliability or ease of use, we set new standards in each of these areas.

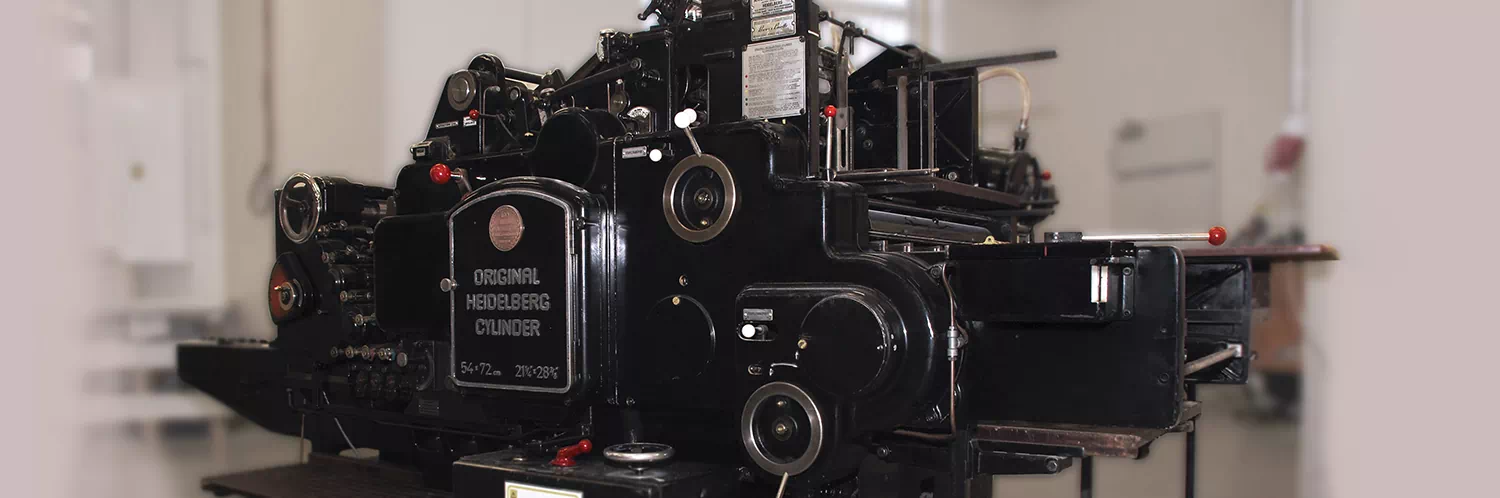

Heidelberg Cylinder Press z 1958 roku

The machine that Drukarnia Skleniarz is proud to have, the Heidelberg Cylinder Press model, was presented for the first time at the DRUPA Fair in 1958. The technical solutions used in the production of this machine placed it among the leaders in concepts and solutions at that time.

The quality of the machine itself can be proven by the fact that our unit, manufactured in the early 1960s, has been working flawlessly for over fifty years. It performs its production tasks every day, is reliable and easy to use – and looks great